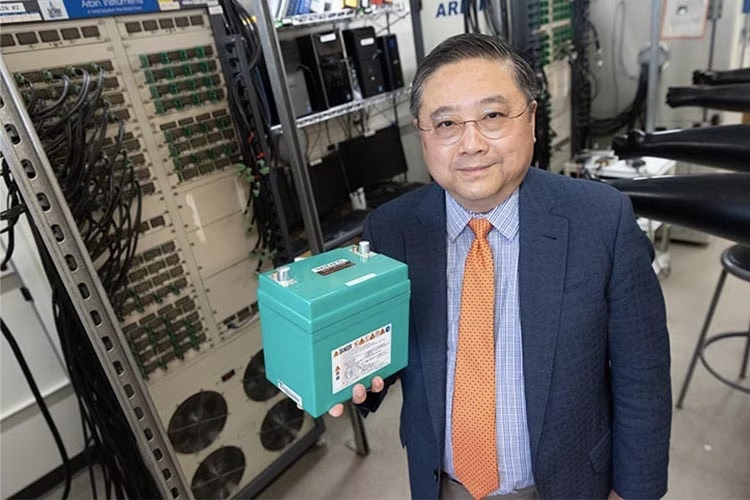

University of Wisconsin-Milwaukee engineers have pioneered a method to convert retired lithium ironphosphate (LFP) batteries from electric vehicles into domestically produced fertilizer, tackling a looming e-waste crisis and creating a new economic stream. Led by Professor Deyang Qu, the breakthrough uses an ion-exchange process to recover key fertilizer ingredients, potentially reducing U.S. reliance on imports.

The world is bracing for a wave of expired electric vehicle batteries, and the most common type—the lithium iron phosphate battery used in many EVs, e-vans, and e-buses—presents a particular problem. Traditional recycling is notoriously expensive and offers little financial return, creating a massive disposal headache. But what if we could see this not as waste, but as a resource? Professor Deyang Qu, a global leader in energy storage research at the University of Wisconsin-Milwaukee, asked that exact question and found an ingenious answer hiding in the chemistry.

“Right now, it costs more to recycle the batteries than the value of what we recover,” Professor Qu stated, highlighting the core economic challenge. “But if we can turn those elements into fertilizer, we not only reduce waste but also support agriculture in Wisconsin and beyond.” This vision is what drove his team to look beyond conventional recycling.

Their innovative strategy, reported by the University of Wisconsin-Milwaukee, leverages a well-established ion-exchange process. They were the first to successfully recover lithium from the spent LFP battery material by replacing it with potassium. The remaining components—phosphorus, potassium, and nitrogen—are the fundamental building blocks of agricultural fertilizer. This elegant solution transforms a costly waste product into a high-value commodity.

READ ALSO: https://www.modernmechanics24.com/post/hanwha-aerospace-partners-akkodis-norway

The motivation is twofold: solving an environmental problem and strengthening national supply chains. “There are only two options to deal with this kind of waste,” explained Professor Qu. “Either the manufacturers or the government will have to pay to dispose of the waste. That’s what inspired us to look for an economically sustainable way.” Fertilizers are a critical product for food security, yet the U.S. currently imports most of the necessary mineral deposits. Creating a domestic supply from recycled batteries would not only be cheaper but also more energy-efficient, as the raw materials wouldn’t need to be mined and transported.

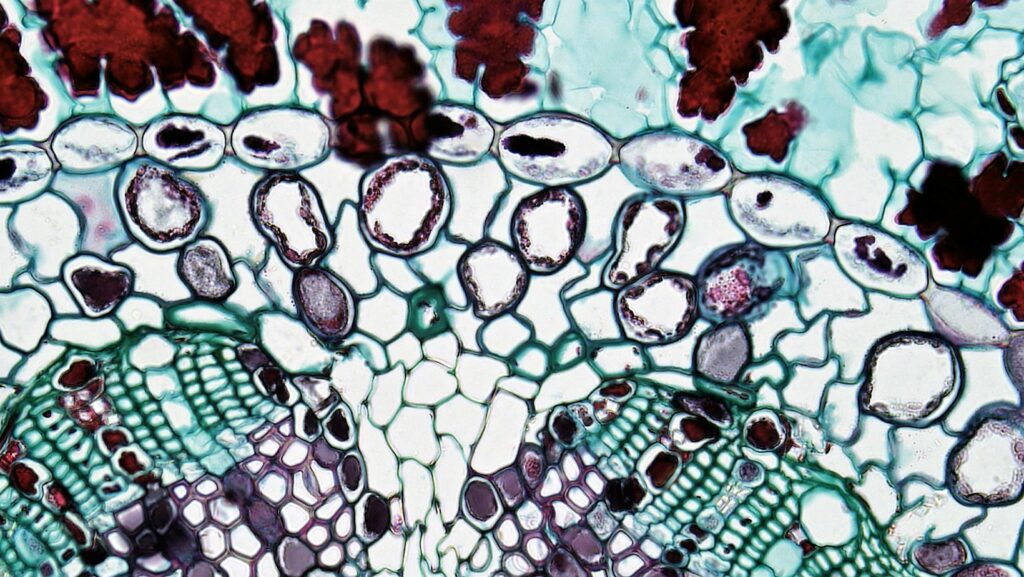

The proof of concept has already been demonstrated with funding from a UWM internal Discovery and Innovation Grant and in collaboration with research partner, the USDA’s Agricultural Research Service. The project now stands at a critical juncture, ready to move from the lab to the field. The next step is to scale up production of the fertilizer to conduct real-world agricultural trials.

WATCH ALSO: https://www.modernmechanics24.com/post/worlds-largest-fusion-project-iter-progress

“Once we obtain support for the recycling-separation portion of the project, we will continue collaborating with the USDA to produce enough material for a one-acre tomato crop trial,” Qu said. The results from this comparative testing, according to UWM, will be essential for proving the fertilizer’s efficacy and attracting commercial partners from the major fertilizer companies.

Wisconsin, with its powerful combination of manufacturing heritage and strong agricultural base, is uniquely positioned to lead this circular economy initiative. The project promises to do more than just manage waste; it aims to create high-tech jobs and provide workforce training in emerging green technologies. By viewing expired EV batteries not as trash but as treasure, Professor Deyang Qu and his team are charging toward a solution that benefits the environment, the economy, and the nation’s farmers.

READ ALSO: https://www.modernmechanics24.com/post/skyborne-codiaq-robotic-weapon