Hyundai Motor Group’s sprawling $7.6 billion Metaplant near Savannah, Georgia, is deploying one of North America’s most advanced robotic workforces to build 500,000 EVs annually, even as the electric vehicle market faces significant headwinds. The facility, which currently employs 1,400 workers but envisions 8,500 direct jobs, represents a massive bet on American manufacturing automation at a time of cooling consumer demand and evolving federal policies.

When this temple of leading-edge factory tech began operations, its timing seemed impeccable. The South Korean automaker was building a defensible bulwark against tariffs and onshoring fervor. But dark clouds soon gathered as consumer adoption of EVs slowed and the U.S. federal government’s $7,500 clean-car tax credit—which had helped hundreds of thousands make the leap to EVs—began phasing out. Despite these challenges, Hyundai executives have chosen to forge ahead with what they call North America’s most automated car factory.

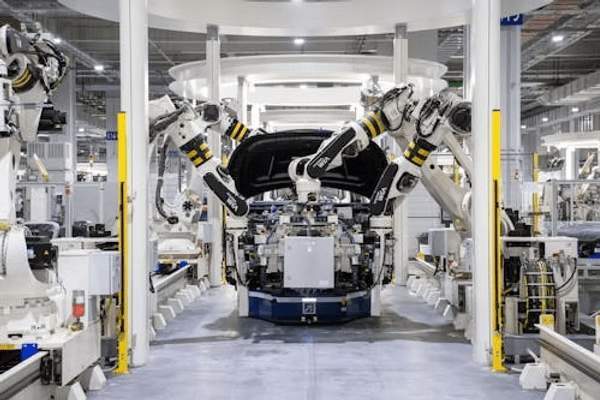

Walking through the cavernous welding hall, visitors might spot fewer than two dozen humans overseeing 475 robots that piece together car chassis in a whirling, metallic dance. The steel stamping plant operates so quietly that no ear protection is required, even as robots stamp out roofs and body panels. Compared to the near-Dickensian Detroit auto factories of the 1980s, this stunning 697,000 square meter facility is a veritable museum of manufacturing art.

“They’re delivering the right parts to the right station at the right time, so you’re no longer relying on people to make those decisions,” says Jerry Roach, senior manager of general assembly at the Metaplant, as reported in the original coverage.

READ ALSO: https://modernmechanics24.com/post/1000-tonne-gold-belt-china-discovery

Roach prefers that his skilled humans focus on craftsmanship—jobs requiring tactile precision that only human hands and vision can accomplish—while robots handle the heavy lifting and repetitive tasks.

The automation extends throughout the facility. When trucks roll into docks, some of the factory’s 850 robots promptly unload their parts. About 300 automated guided vehicles (AGVs) glide silently across the factory floor with no tracks required, trained to smartly stop for humans.

These AGVs operate within an AI-based procurement-and-logistics system, allocating and delivering components for “just in time” delivery to avoid wasted time, space, and money.

For the first time at a Hyundai factory, collaborative robots sophisticated enough to work safely near people are installing bulky, heavy doors on the assembly line. “Guess what? Robots do that perfectly, always putting the door in the exact same place,” Roach noted.

WATCH ALSO: https://www.modernmechanics24.com/post/robot-kicked-and-dragged-in-stress-test

The technological showcase doesn’t end there—Spot, the robotic quadrupeds from Hyundai-owned Boston Dynamics, use camera vision and sensors to sniff out potential welding defects. These four-legged bots may soon have a biped master: Atlas, the humanoid robot, also from Boston Dynamics, which Hyundai plans to deploy in its global factories.

The human workers who Hyundai calls “Meta Pros” earn an average of $58,100 annually—35 percent higher than the average in Bryan County, Georgia. They park their cars beneath solar roofs that generate up to 5 percent of the plant’s electricity, while a fleet of 21 hydrogen fuel-cell trucks from Hyundai-owned Xcient carries parts from suppliers, emitting zero tailpipe emissions. The automaker’s goal is to obtain 100 percent of the Metaplant’s energy from renewables by 2030.

The facility hasn’t been without controversy. The adjacent $4.3 billion battery plant joint venture between Hyundai and LG Energy Solution made headlines in September when U.S. Immigration and Customs Enforcement agents staged a workplace raid that led to more than 300 South Korean workers being detained and deported. The episode highlighted the transnational cooperation—and tensions—inherent in importing a leading-edge manufacturing operation.

READ ALSO: https://www.modernmechanics24.com/post/china-unveils-as700-airship-in-shaoxing

Yet Hyundai continues to expand its American footprint, already building a second battery plant in Georgia and a steel plant in Louisiana as part of an expanded pledge of $21 billion in U.S. investment through 2028. From nearby Interstate 16, Georgia drivers can see freshly painted Ioniq 5s and 9s moving along a conveyor on a windowed bridge—an intentional glimpse of what their tax dollars helped create after $2.1 billion in state subsidies.

In a suddenly inhospitable climate for EVs, there’s nothing automatic about building and selling the cars. But as the original reporting concluded, Hyundai and other automakers will keep trying—they don’t have any other choice.

WATCH ALSO: https://www.modernmechanics24.com/post/worlds-first-motorbike-backflip-between-moving-trucks