In a collaborative study, researchers from Tohoku University, Iwate University, the Japan Aerospace Exploration Agency (JAXA), the National Astronomical Observatory of Japan, Tokyo City University, and Kyoto University have developed a groundbreaking copper-based alloy that demonstrates a remarkable shape memory effect at temperatures as low as –200°C.

Shape memory alloys are materials that can be bent or deformed at low temperatures but return to their original shape when heated—almost as if they “remember” their initial form, similar to memory foam. This newly developed alloy shows great promise for use in space equipment and hydrogen-related technologies, where operating temperatures often fall below –100°C.

Conventional shape memory alloys made from nickel-titanium (Ni-Ti) have long been valued for their useful properties, but they lose their shape memory function at temperatures below –20°C. On the other hand, while some existing alloys can function below –100°C, they aren’t practical for real-world applications.

This study successfully tackled that challenge by developing the first actuator material capable of delivering significant mechanical output at temperatures below –100°C. Actuators—components that convert energy into movement—are essential not only in spacecraft but also in many everyday technologies.

READ ALSO: Mediterranean Beetles Defy Norm as Rare Insects That Can See Red

READ ALSO: Mediterranean Evaluation Begins for Floating Nuclear Power Plants

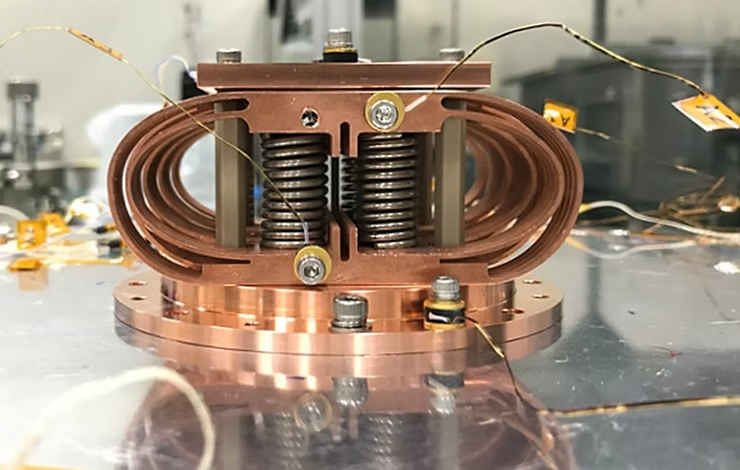

The research team created a prototype of a mechanical heat switch using their newly developed Cu-Al-Mn alloy as the actuator. This switch performed reliably at –170°C, toggling between contact and non-contact states in response to temperature changes to regulate heat flow. Notably, the alloy’s operating temperature can be fine-tuned by adjusting its composition.

“We were thrilled to see it working at –170°C,” said Toshihiro Omori of Tohoku University. “Other shape memory alloys just can’t function at those temperatures.”

The Cu-Al-Mn alloy marks a breakthrough as the first actuator material capable of delivering significant mechanical output at temperatures below –100°C. This advancement opens up new possibilities for developing high-performance actuators that can function in extreme cryogenic environments—something that was previously unattainable.

One promising application is a dependable mechanical heat switch for cooling systems in space telescopes. Thanks to their simple design and compact size, these switches are poised to become vital components in future space missions. They also hold strong potential for supporting carbon-neutral technologies, such as hydrogen transportation and storage.