A new method utilizing soundwaves to separate materials for recycling may help prevent the release of harmful chemicals into the environment.

Scientists at the University of Leicester have made significant progress in fuel cell recycling by developing an efficient technique to extract valuable catalyst materials and fluorinated polymer membranes (PFAS) from catalyst-coated membranes (CCMs).

This advancement tackles pressing environmental concerns linked to PFAS—commonly known as ‘forever chemicals’—which are persistent pollutants found in drinking water and associated with serious health risks. The Royal Society of Chemistry has called for government action to lower PFAS levels in the UK’s water supply.

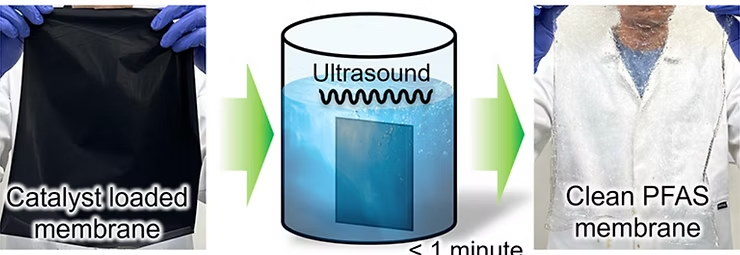

Fuel cells and water electrolysers, which are vital for hydrogen-based energy systems used in transportation, rely on CCMs that include costly platinum group metals. However, the strong bonding between the catalyst layers and PFAS membranes has posed challenges for recycling. The Leicester team has created a scalable approach using organic solvent soaking combined with water-based ultrasonication to successfully separate these components, marking a major step forward in sustainable recycling technology.

Dr. Jake Yang from the University of Leicester’s School of Chemistry stated, “Our method is both simple and scalable, allowing us to separate PFAS membranes from valuable metals without using aggressive chemicals. This marks a significant shift in how fuel cells are recycled. While fuel cells have long been seen as a promising clean energy solution, the high cost of platinum group metals has limited their widespread adoption. Creating a circular economy for these metals brings us closer to making this technology viable.”

Following this success, researchers introduced a continuous delamination process that uses a custom-designed blade sonotrode powered by high-frequency ultrasound. This technique rapidly splits membranes by generating pressure-induced collapsing bubbles, allowing for the quick and room-temperature separation of precious catalysts. The method is not only sustainable but also cost-effective, opening the door for broader implementation.

This innovative research was conducted in partnership with Johnson Matthey, a global leader in sustainable technology. Collaborations between academia and industry like this highlight the power of teamwork in advancing scientific innovation.

Ross Gordon, Principal Research Scientist at Johnson Matthey, commented, “Using high-intensity ultrasound to separate catalyst-coated membranes is a breakthrough for fuel cell recycling. At Johnson Matthey, we’re proud to be part of this effort to drive sustainable and economically feasible hydrogen energy solutions.”

As demand for fuel cells increases, this advancement supports the development of a circular economy by enabling efficient recycling of key components. The researchers’ work contributes to making clean energy technology more affordable and environmentally responsible.