Researchers at the Aero Engine Corporation of China (AECC) have successfully completed the first single-engine flight test of a domestically developed, ultra-lightweight miniature turbojet engine, with over three-quarters of its components built using 3D printing. The engine powered a target drone to an altitude of 6,000 meters at a speed of Mach 0.75 during the 30-minute flight, reported Xinhua.

This successful test marks a significant leap in China’s propulsion technology, demonstrating the viability of additive manufacturing for producing complex, high-performance aviation engines.

The engine is the country’s first 3D-printed, ultra-lightweight miniature turbojet engine in the 160-kilogram thrust class to complete a flight test. Its performance in the air validates years of research and development focused on simplifying engine construction while boosting capabilities.

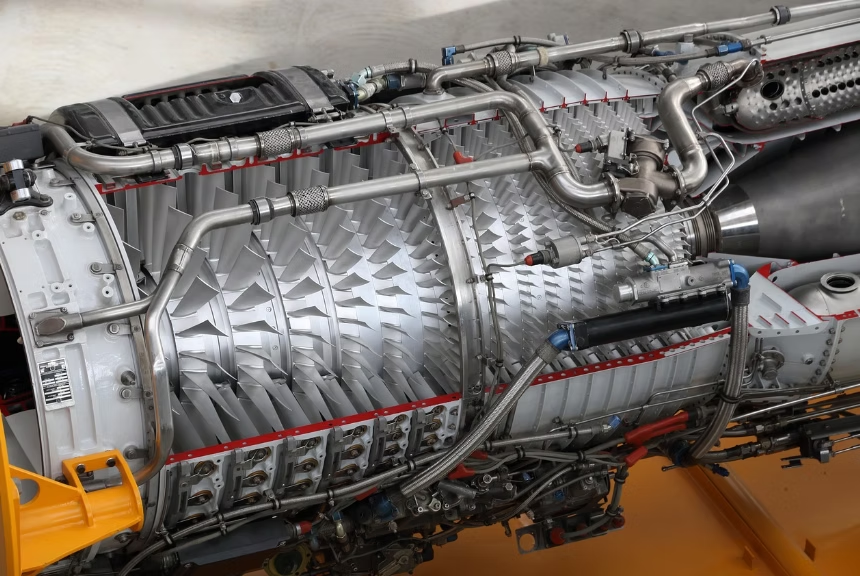

The extensive use of 3D printing was central to the engine’s design success. All of its rotating parts, which account for more than 75 percent of the total engine weight, were manufactured using this advanced technique.

READ ALSO: https://www.modernmechanics24.com/post/type-076-sichuan-drone-ship-trials-begin

This innovative approach dramatically reduced the number of individual parts required, which in turn lowered the overall weight, simplified the assembly process, and made the engine easier to operate and maintain.

According to Xinhua, the engine utilizes a multi-disciplinary topology optimization design that works in concert with 3D printing to achieve its lightweight and high-performance goals.

This means engineers used sophisticated software to design components that are both incredibly strong and as light as possible, with complex internal structures that could only be produced through additive manufacturing. This represents a fundamental shift away from traditional machining and forging methods.

The flight itself was a critical step beyond a previous captive-carry test conducted in July. Operating normally and stably throughout the flight, the engine proved its reliability at higher altitudes and in more complex flight environments than ever before.

WATCH ALSO: https://www.modernmechanics24.com/post/black-hole-flare-outshines-10-trillion-suns

This successful test of the engine’s compatibility with the aircraft airframe opens the door for more advanced demonstrations, laying a solid foundation for future flights targeting even higher altitudes and greater speeds.

The implications of this breakthrough extend far beyond a single engine. With the increasing application of design optimization and 3D printing technology in the aero-engine sector, the development cycle for future engines is expected to be significantly shortened.

This acceleration is crucial for China’s broader strategic goal of achieving independent research, development, and manufacturing of advanced aviation propulsion systems, reducing reliance on foreign technology.

READ ALSO: https://www.modernmechanics24.com/post/china-byd-ev-withstands-lightning-strikes