A research team from TU Graz and the Vellore Institute of Technology in India is working on creating a 3D-printed artificial skin containing living cells to test cosmetic nanoparticles without relying on animal testing.

introduced limitations on the use of animal testing for cosmetics and their ingredients across the EU. As a result, there is a growing effort to find alternative methods for assessing the absorption and toxicity of nanoparticles found in products like sunscreen.

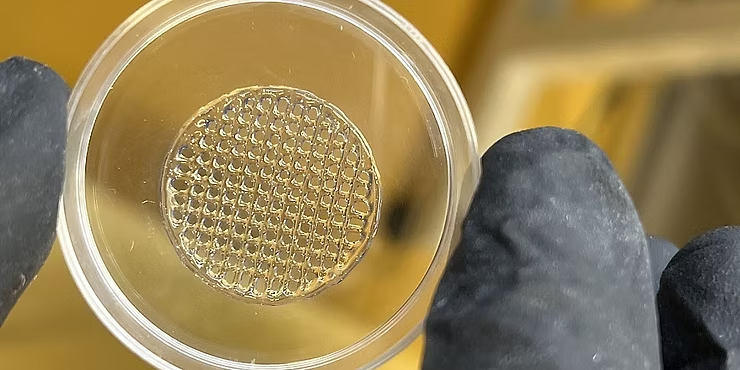

Researchers from Graz University of Technology (TU Graz) and the Vellore Institute of Technology (VIT) in India are developing artificial skin models that replicate the three-layered structure and mechanical properties of natural human skin. These models are created through 3D printing using hydrogel mixtures combined with living cells. The initial skin prototypes are now prepared for testing nanoparticles.

Hydrogels That Support Skin Cell Survival and Growth

“The hydrogels used in our 3D-printed skin models must meet several critical requirements,” explains Karin Stana Kleinschek from the Institute of Chemistry and Technology of Biobased Systems at TU Graz. “They need to be compatible with living skin cells, allowing the cells not only to survive but also to grow and multiply.”

The foundation for these stable and 3D-printable structures lies in specialized hydrogel formulations developed at TU Graz. With their high water content, hydrogels provide an ideal environment for cell integration and development. However, this same water content necessitates mechanical and chemical stabilization methods to maintain the structure of the 3D prints.

To address this, TU Graz is focusing on developing cross-linking techniques for stabilization. Ideally, these techniques mimic natural processes, operating under gentle conditions without the use of toxic chemicals. Once stabilized, the printed skin models are sent to the research partners in India, who assess their durability and toxicity in cell cultures. A model is only considered a true skin imitation if skin cells remain viable and develop into skin tissue over two to three weeks in culture. Once confirmed, these skin models can be used for further cosmetic testing on a cellular level.

Successful tests

Initial tests of the 3D-printed hydrogels in cell cultures have shown highly promising outcomes. The cross-linked materials proved to be non-toxic to cells and demonstrated strong mechanical stability. “The next phase involves using these 3D-printed skin models to test nanoparticles,” says Karin Stana Kleinschek. “This marks a significant achievement in the collaborative research between TU Graz and VIT. Our long-standing experience in material development for tissue models, combined with VIT’s strengths in molecular and cell biology, has created a highly effective partnership. We are now jointly working on refining the hydrogel formulations and verifying their potential as an alternative to animal testing.”