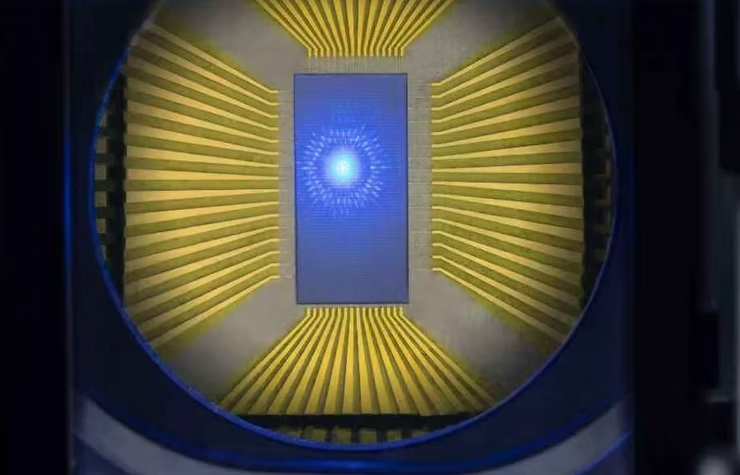

Researchers at Tianjin University have introduced an innovative non-destructive testing technique for micro-LED wafers, addressing a persistent industry challenge with a unique “soft-touch” method.

Micro-LEDs are considered a key technology for future high-end displays, where near-perfect fabrication yields are critical for maintaining quality and minimizing repair expenses. However, the lack of reliable non-destructive testing at the wafer level has long posed a significant technical hurdle.

A research team led by Professor Huang Xian from Tianjin University’s School of Precision Instrument and Opto-electronics Engineering has successfully bridged a key technological gap. Their groundbreaking work was published on June 13 in the esteemed journal Nature Electronics.

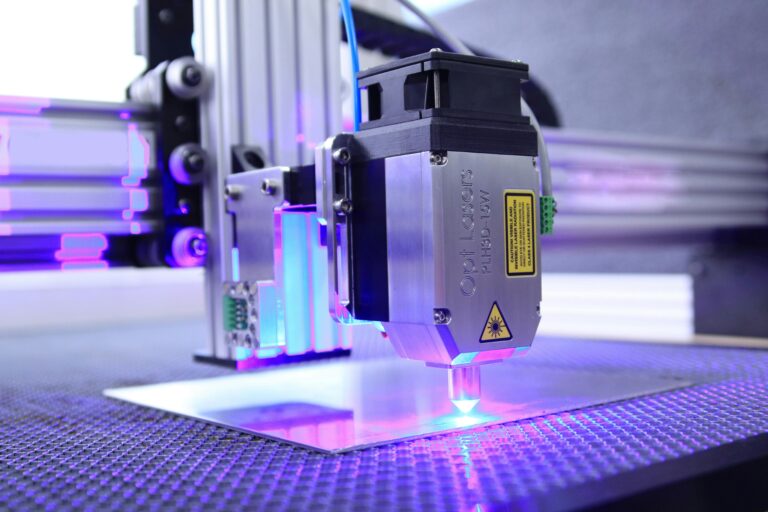

The team developed a flexible 3D probe array that conforms to the micro-scale surface of micro-LED wafers, applying an ultra-light pressure of just 0.9 MPa—akin to a soft breath. This gentle contact enables high-throughput electrical testing without causing scratches or damage to the wafer.

READ ALSO: Electric vehicles and their warning sounds are hard to detect when moving at low speeds

READ ALSO: From Microbes to Complex Cells: Tracing the Origins of Life

READ ALSO: New quantum sensing technology reveals subatomic signals

“Our flexible probes exert only one ten-thousandth the pressure of traditional rigid probes,” said Professor Huang. “This not only protects the wafer surface but also greatly enhances the probes’ durability. Even after one million testing cycles, they maintain their original condition.”

To complement their innovation, the team also designed a specialized measurement system that seamlessly integrates with the flexible probe array. This combined setup offers an effective solution for process monitoring and yield assessment in micro-LED production.

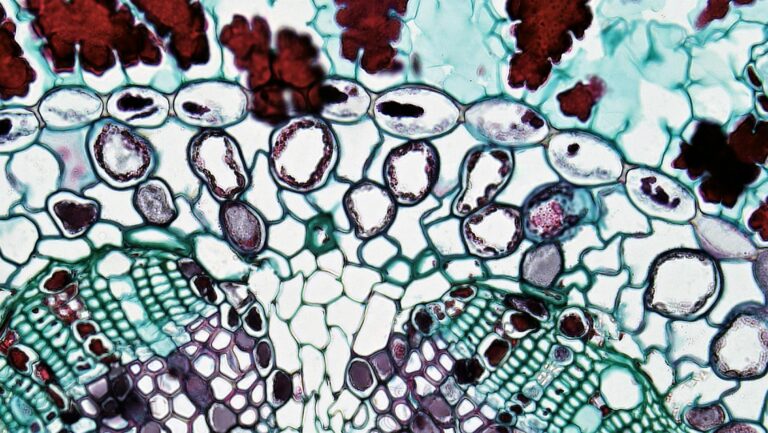

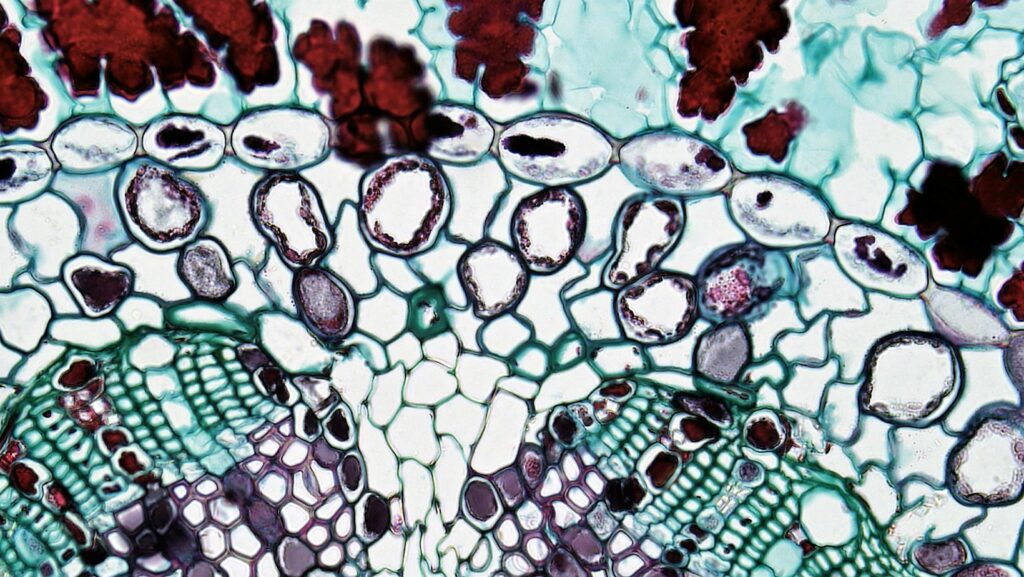

“This advancement lays a new foundation for the field,” Huang stated. “It addresses a critical gap in micro-LED electroluminescence testing and opens the door to wider use in advanced wafer inspection and biophotonics.”

The technology is currently being advanced toward commercialization at the Tiankai Higher Education Innovation Park. It holds promise as a scalable, cost-effective, and non-destructive testing method for the fast-growing micro-LED sector, while also broadening the real-world applications of flexible electronics in a range of cutting-edge industries.