If you’ve ever lived near a construction site, you know the soundtrack all too well: the constant, rumbling roar of diesel generators. It’s been the unavoidable background noise of progress for decades. But what if that noise, along with the plumes of smoke and the endless fuel deliveries, could just… stop? What if a construction site could be powerful, yet quiet? Ambitious, yet clean?

That future is no longer a distant dream. The game is changing, and it’s being powered by the sun. The latest leap forward is a new kind of power station built for the most demanding construction and infrastructure projects.

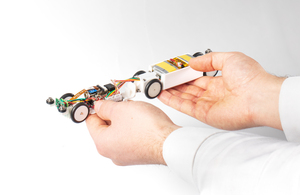

Developed by Prolectric, the ProCharge BESS is a three-phase, hybrid-ready solution built for performance, flexibility and sustainability. It features 120kWh battery storage and deployable 5,280W solar array made up of 12x 440W high-efficiency panels.

Solar-powered System

This isn’t a simple solar panel setup; it’s a robust, three-phase energy system designed to tackle high-load applications head-on, dramatically cutting the cord from diesel.

Imagine a skid-mounted unit that you can drop onto a site. It comes with its own deployable array of high-efficiency solar panels, capable of generating over 5,000 watts of clean energy. Its heart is a massive 120kWh battery bank, and it can output enough power—up to 45kVA—to run a large site compound.

Read Also: Hanwha Aerospace signs partnership with GA-ASI for new UAS tech

The real genius, however, lies in its flexibility. This system isn’t dogmatic; it’s pragmatic. It seamlessly integrates with existing diesel or HVO generators, creating a hybrid setup that uses the fossil fuel as a last resort, not a first option.

Solar system’s prototype already underwent trials

The results from early testing are staggering. On a major highway project, a prototype of this system was put through its paces. In just five months, it slashed fuel costs by over £32,500 and prevented a staggering 62,500 kilograms of carbon dioxide from entering the atmosphere. Project those savings out over a year, and we’re talking about £69,000 staying in the budget and 150,000 kg of CO₂ eliminated. That’s the equivalent of taking dozens of cars off the road for a year, all from a single, quiet power unit on one site.

This technology does more than just save money and the planet—it fundamentally changes how a site can operate. Its low-noise performance means night shifts no longer have to mean noise complaints from the neighborhood. With enough clean capacity to charge electric telehandlers, dumpers, and other machinery, it becomes the beating heart of a fully electric, zero-emission site. It’s enabling a smarter, more connected worksite, all monitored and optimized remotely.

This is the promise of a true solar-first approach. Instead of tacking solar onto old-fashioned diesel tech, this system was engineered from the ground up to harness the sun. It’s a clear signal that for heavy industry, the transition to clean energy isn’t a compromise on power; it’s an upgrade for performance, profitability, and our collective future. The quiet revolution on the construction site has begun, and it’s powered by light, according to Prolectric.

Read Also: China’s New Z-20T Assault Helicopter Impresses in Rare Air Display

Watch: Swedish firm has recently run a self-driving truck in Europe