Chinese scientists at the Laoshan Laboratory in Shandong province have launched a first-of-its-kind facility that produces fresh water for a record-low 2 yuan (US$0.28) per cubic metre—cheaper than Beijing’s tap water—while simultaneously generating green hydrogen from seawater. This “one-in, three-out” system, powered by industrial waste heat, represents a radical leap in sustainable resource technology.

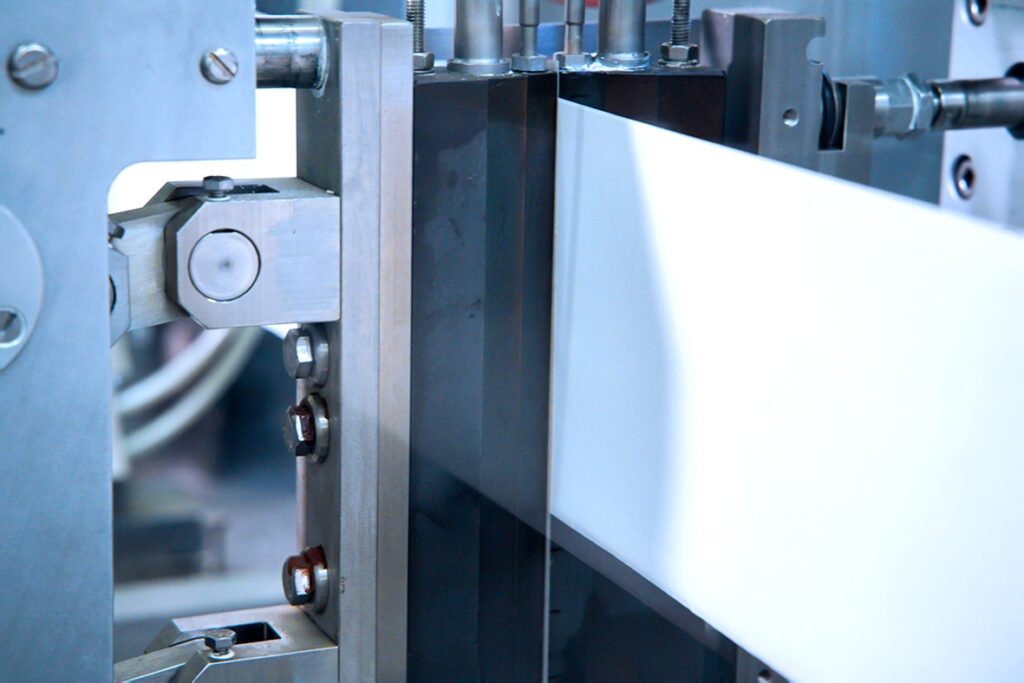

Imagine turning the vast, salty ocean into a source of both ultra-cheap drinking water and clean-burning fuel, all while using the discarded heat from nearby factories. That’s precisely what a groundbreaking pilot plant in the coastal city of Rizhao has achieved, operating continuously for over three weeks.

As reported by the Shandong official news outlet Dazhong, the facility processes 800 tonnes of seawater annually to deliver a triple output: 450 cubic metres of ultra-pure fresh water, 192,000 standard cubic metres of green hydrogen, and 350 tonnes of mineral-rich brine for industrial use.

The economic and environmental implications are staggering. The cost of 2 yuan per cubic metre undercuts not only local tap water prices but also existing desalination tech. For context, a similar waste-heat-powered plant in Jinan costs 4 yuan, and desalinated water at California’s massive Carlsbad plant runs about US$2.21 per cubic metre. “This is not just about producing a canister of hydrogen; it opens up a new path for ‘extracting energy from the sea’,” Qin Jiangguang, a senior engineer at the Laoshan Laboratory, told Dazhong.

READ ALSO: https://www.modernmechanics24.com/post/key-mass-data-xray-burst-reaction-rate

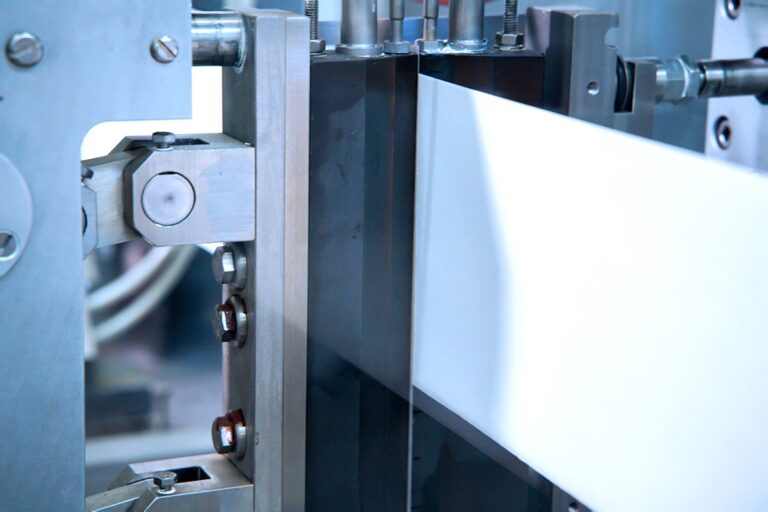

The core innovation lies in solving a historic engineering puzzle: using seawater directly for electrolysis to make hydrogen. Conventional systems require precious fresh water because impurities in seawater, like calcium and chloride ions, rapidly corrode and clog equipment.

The Shandong team, however, developed corrosion-resistant catalysts and precise regulation technologies to use natural seawater directly. Simultaneously, they harness low-grade waste heat from adjacent steel and petrochemical plants to power the desalination process, eliminating the need for separate, energy-intensive cooling units. This synergy boosts the system’s power utilization rate by over 20% compared to standard freshwater electrolysis.

The result is a perfectly circular model. The plant consumes seawater and waste heat—two abundant, low-value inputs—and outputs high-value resources. The produced hydrogen, created at an energy cost of 4.2 kilowatts of electricity per cubic metre, is enough to power 100 buses for 3,840km every year. According to the report from Dazhong, this “validates a new paradigm for zero-carbon hydrogen energy supply that is deeply aligned with China’s coastal industrial layout,” said Li Jiawei, an assistant researcher at the Laoshan Laboratory.

WATCH ALSO: https://www.modernmechanics24.com/post/tron1-hyper-real-dinosaur-robot

This breakthrough could redefine water and energy economics, especially for coastal industrial hubs and arid regions. It offers a powerful tool for carbon reduction and a practical engine for green transformation, turning environmental liabilities like industrial waste heat into critical assets. By proving that fresh water and green fuel can be produced from the sea at costs cheaper than conventional sources, the Laoshan Laboratory team has provided a compelling “Chinese solution” with global potential for addressing intertwined water and energy crises.